The Impregnated Diamond Dresser shares notable similarities with the Multipoint diamond dresser. In this dresser, crushed diamond grit, available in both Natural and Synthetic grades, is arranged in several layers in a random pattern. This tool utilizes multiple small diamonds working in concert to deliver outstanding performance during the dressing process. To achieve optimal results, it’s essential for the diamond particles to possess at least twice the size of the grinding wheel’s grain that they are intended to dress. Tools with a higher diamond content tend to be more efficient in this regard. These dressers are particularly well-suited for applications involving fine and delicate grinding wheels where a lower surface finish is desired.

The Impregnated Diamond Dresser shares notable similarities with the Multipoint diamond dresser. In this dresser, crushed diamond grit, available in both Natural and Synthetic grades, is arranged in several layers in a random pattern. This tool utilizes multiple small diamonds working in concert to deliver outstanding performance during the dressing process. To achieve optimal results, it’s essential for the diamond particles to possess at least twice the size of the grinding wheel’s grain that they are intended to dress. Tools with a higher diamond content tend to be more efficient in this regard. These dressers are particularly well-suited for applications involving fine and delicate grinding wheels where a lower surface finish is desired.

We as manufacturer of Impregnated Diamond Dressers offer precision engineered diamond dressing tools that are designed for high enhancing accuracy, and productivity of our clients. As an exporter of Impregnated Diamond Dressers at wholesale price, these tools are checked by of quality assistants to ensure its high quality standards. Further, we as supplier of Impregnated Diamond Dressers offer these industrial diamond tools as per the requirement of our clients.

Being a manufacturer of impregnated diamond dressing tools, we provide quality manufactured diamond dressing tools that are meant to improve performance and reliability. As an exporter of impregnated diamond dressers at wholesale prices, these instruments are inspected by quality experts to guarantee that they meet high quality requirements. Furthermore, as a supplier of Impregnated Diamond Dressers, we provide these industrial diamond tools to meet our customers’ needs.

ADVANTAGES OF IMPREGNATED TOOL:

- Dressing time is reduced as higher feed rates can be used.

- They are tougher and more resistance.

- These tools can be used completely without any requirement of maintenance.

- Extend wheel life by less stock removal per dressing.

- No resetting or re-lapping required.

- These tools are inexpensive and easy to use.

TO GET THE MAXIMUM TOOL LIFE For Impregnated Diamond Dressers:

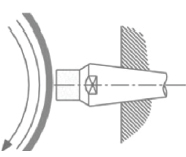

- Set the Grit Impregnated tool into the center of the grinding wheel so that tool face gets completely in contact with the wheel. (Fig. 1)

- Depth of cut should not exceed more than 0.01-0.04 mm.

- Use plenty of coolant to increase the tool life.

- The mounting must be vibration free, with the clamping length as short as possible.

- Grit Impregnated must be used with higher cross feed velocity rates than single point or blade dressing tools as their effective width is generally much greater.

- Slower cross feed rates would lead to high overlap ratios and thus may blunt the

- Grinding wheel.